China Leading Aerated Concrete Equipment Manufacturer

we provide a one-stop solution for your autoclaved aerated concrete block and panel making projects, from scheme design to equipment manufacturing, installation, and commissioning after-sales services.

Comprehensive Solution Capability

Feasibility Analysis

Plant Layout Design and Implementation

Machine Selection and Manufacturing

Machine Installation and Commissioning

Control System Software Upgrade

Online and On-site Technical Support

1. Raw Materials Preparation Section

Proper control and management of the raw materials preparation contribute to the production of high-quality AAC materials for construction applications.

This process involves the following equipment:

Jaw crusher

Bucket elevator

Belt conveyor

Ball mill

Dust collector

Screw conveyor

Slurry agitator

Slurry pump

2. Batching & Pouring Section

Proper batching, mixing, and pouring are essential to produce high-quality autoclaved aerated concrete blocks or panels.

This process involves the following equipment:

Powder & Slurry electric scale

Aluminium slurry mixing machine

Pouring mixer

Ferry carriage

Bubble removing device

Aluminium Slurry Mixing Machine

The goal is to achieve consistent dispersion of aluminum powder and other components to ensure proper expansion and curing during autoclaving.

Pouring Mixer

The pouring mixer is used to evenly mix and fully react the production raw materials, and then pouring the mixed slurry into the mold frame in time.

Bubble Removing Device

To ensure the structural integrity and uniform density of the AAC blocks, it's important to remove excess air bubbles from the slurry before it sets.

3. Precuring & Cutting Section

Both the precuring and cutting steps are crucial for producing high-quality AAC products with consistent properties and dimensions.

This process involves the following equipment:

Mould and side plate

Traction machine

Friction wheel

Oiling system

Tilting & demoulding crane

Cutting machine

Mould and Side Plate

Side plates are used in conjunction with molds to create the desired shape and size of the AAC blocks. By adjusting plates to produce different blocks.

Tilting and Demoulding Crane

The tilting and demoulding crane is a specialized equipment designed to handle the delicate process of releasing the cured AAC blocks from the molds.

4. Grouping & Autoclaving Section

Once the blocks have gained sufficient strength and the chemical reactions are complete, they are grouped together for the autoclaving process.

This process involves the following equipment:

Tilting table

Grouping crane

Steaming wagon

Autoclave

Tilting Table

The tilting table facilitates work to make the AAC block turn 90°, efficient and stable turning over, reducing the difficulty and cost of civil construction.

Grouping Crane

This equipment is used for smoothly and precisely grouping the newly produced AAC blocks before they are subjected to the autoclaving process.

5. Packing Section

Proper packaging ensures that the aerated concrete products remain in good condition, maintaining their structural integrity and appearance until they are ready to be used in construction projects.

This process involves the following equipment:

Separator

Combination platform

Grabber

Pallet feeder

Chain conveyor

Strapping machine

Side plate clean machine

Side plate roller

Chain Conveyor

The tilting table facilitates the initial casting, mixing, and curing of the blocks before they are ready for autoclaving, and packaging.

Grabber

The tilting table facilitates the initial casting, mixing, and curing of the blocks before they are ready for autoclaving, and packaging.

Strapping Machine

The tilting table facilitates the initial casting, mixing, and curing of the blocks before they are ready for autoclaving, and packaging.

Automation System

Stability

All electrical components of our equipment are imported brands, Schneider inverters, Omron/Pepperl+Fuchs switches, and Siemens programmable controllers PLC.

Safety

The Schneider motor protector is equipped to avoid damage to the equipment due to current overload, and also equipped with a one-button start-stop function.

Integrate

Can set up centralized management operation stations for each production section, and can realize remote monitoring for management and troubleshooting.

Starting an AAC Block Plant?

Unleash your AAC block plant (mini, medium or large size) production potential with our industry-leading equipment. Maximize profits and minimize hassle. Your success story begins here!

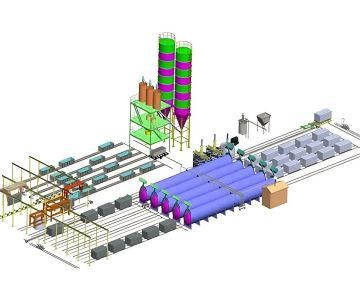

Mini AAC Plant

Capacity: 200-500CBM/Day

Factory Area: 3000 -5000M2

Main Machine: 4.2m Machines

Autoclave: 4 Sets

Cutting Machine: 1 Set

Mould and Side Plate: Mould 15pcs, side plate 162pcs

Other Machine: 1 set of ferry carriages and 3 sets of cranes

Total investment: $400,000 - $1,000,000

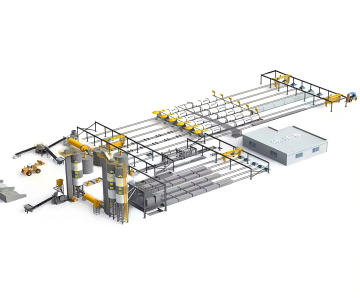

Medium AAC Plant

Capacity: 600 -1000CBM/Day

Factory Area: 5000 -10000M2

Main Machine: 4.8m Machines

Autoclave: 7 Sets

Cutting Machine: 1 Set

Mould and Side Plate: Mould 33pcs, side plate 213pcs

Other Machine: 3 sets of ferry carriages and 4 sets of cranes.

Total investment: $1,245,000 - $1,940,000

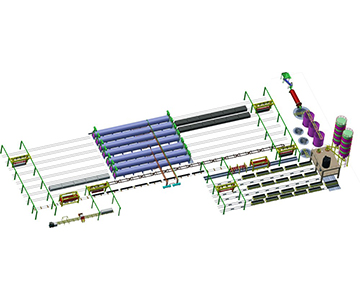

Large AAC Plant

Capacity: 1000 -1500CBM/Day

Factory Area: >10000 m2

Main Machine: 6m Machines

Autoclave: 11 Sets

Cutting Machine: 1 Set

Mould and Side Plate: Mould 53pcs, side plate 308pcs

Other Machine: 4 sets of ferry carriages and 6 sets of cranes.

Total investment: $2,180,000 - $3,470,000